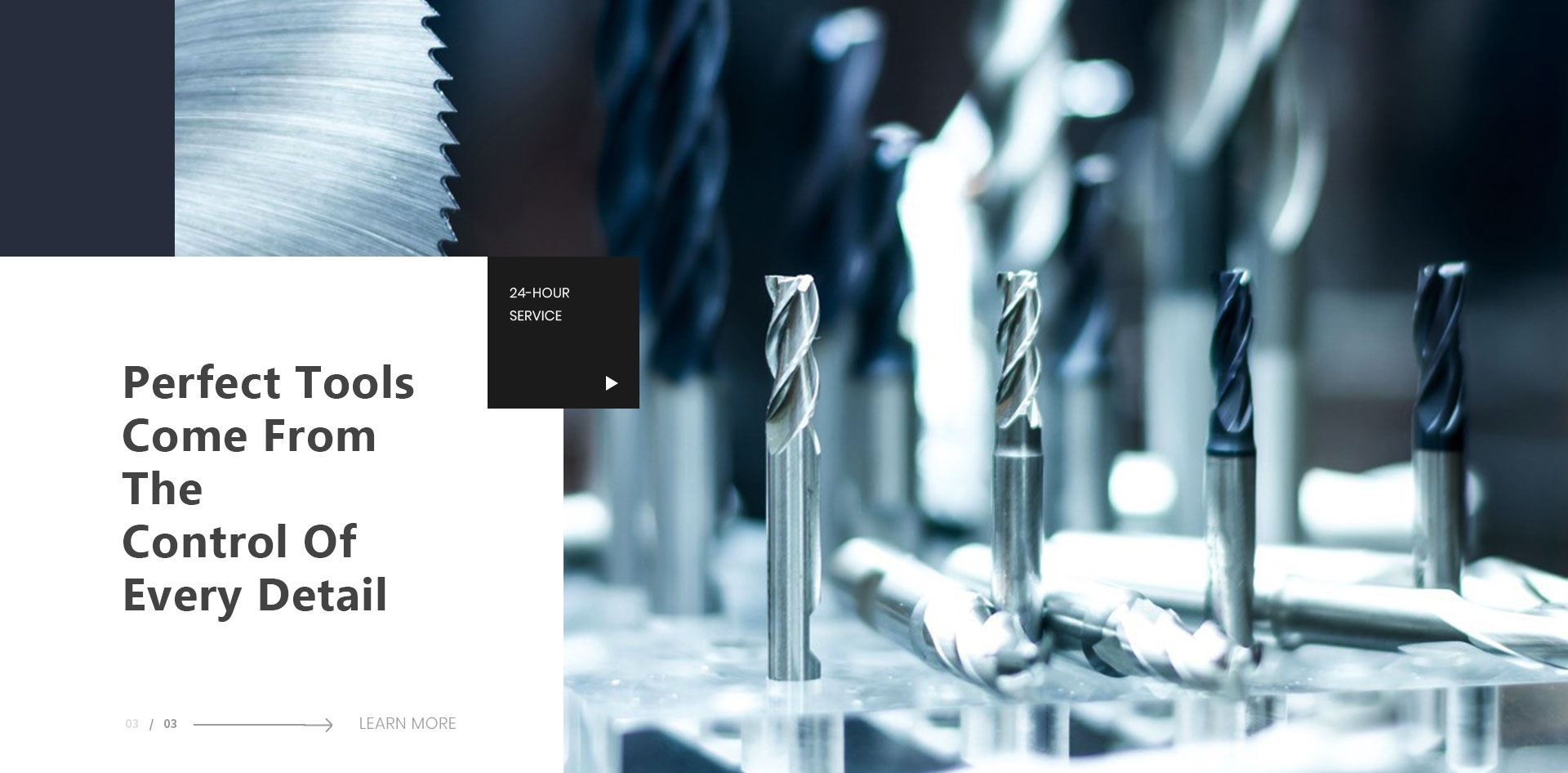

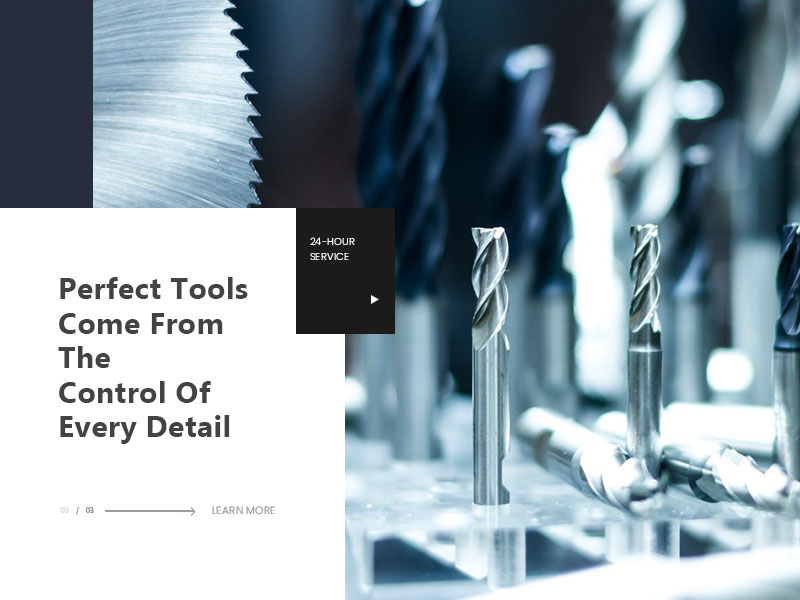

Featured Products

Our high quality tools are produced by advanced CNC grinding machines from Germany, USA and Switze.

All the tools are widely applied in the area of machinery processing, ke automobile, mould, plastic and so on.

Who We Are

Our main products are carbide milling cutter,solid carbide end mill,ball nose end mill,solid carbide drill,2 flute end mill...

- 1988

BUSINESS OF CUTTING TOOLS

- 2004

CREATE COMPANY

- 2011

INTERNATIONAL TRADE

- 300

CUSTOMER

Contact us to get the best product solution and customize your own solution.

Latest News

In the process of practical application, we learned that the cemented carbide drill bit is made of a complete cemented carbide bar by precision grinding with a 5-axis automatic machining center. So what are the characteristics and applications of the carbide twist drill?

Read MoreHigh-Performance Carbide End Mills are used for machining grooves, step surfaces, etc. . The cutter teeth are on the circumference and end face. When High-Performance Carbide End Mills have end teeth through the center, they can be fed axially.

Customized Cutting Tools Mill End's main cutting edge is on a cylindrical surface, and the cutting edge on the end face is a sub-cutting edge.

Micro Carbide Ball End Mill is a kind of reasonable new structural cutter for machining complex curved surfaces on an NC machine tool.

A solid carbide milling cutter is mainly used for milling upper surface, step, groove, forming surface processing, and cutting the workpiece.

Because there is a small gap between the solid carbide milling cutter and the cutter holder, the cutter may vibrate during the machining process.