Carbide end mill high quality is the right way to use

Jun 08, 2021|

Jun 08, 2021| View:1225

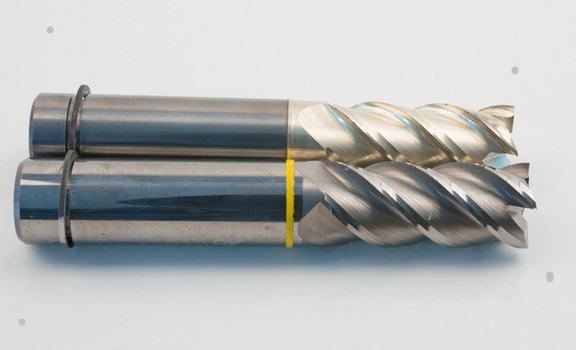

View:12251.Carbide end mill high quality clamping

Carbide end mill high quality is usually coated with anti-rust oil when it leaves the factory, if non-water-soluble cutting oil is used when cutting, a mist oil film will be attached to the inner hole of the tool holder, when the oil film exists on both the shank and the tool holder, it is difficult for the tool holder to clamp the shank firmly, and the end mill will easily fall off during processing. Therefore, before the end mill is clamped, the shank of the end mill and the inner hole of the tool holder should be cleaned with cleaning liquid and dried before clamping.

Since there is a small gap between the end mill and the tool holder, the tool may vibrate during the machining process. The vibration will make the end mill circumferential edge eat unevenly and increase the cutting expansion than the original value, which will affect the machining accuracy and tool life.

3.Carbide end mill high quality end edge cutting

In the CNC milling processing of mold and other workpiece cavities, when the cutting point is a concave part or deep cavity, the extension of the end mill needs to be lengthened. If a long end mill is used, the deflection of the tool will cause vibration and tool breakage.

Therefore, if only the cutting edge near the end of the tool is required to participate in the machining process, it is better to use a short-edge long-shank end mill with a longer total tool length.

4. The choice of cutting parameters

The choice of cutting speed mainly depends on the material of the workpiece to be machined; the choice of feed rate mainly depends on the material of the workpiece to be machined and the diameter of the end mill. Some foreign tool manufacturer's tool samples with cutting parameters selection table, can be referred to.

The use of smooth milling is conducive to preventing damage to the cutting edge, which can improve tool life. But there are two points need to pay attention to.

① such as the use of ordinary machine tool processing, should try to eliminate the clearance of the feed mechanism.

②When the surface of the workpiece is left with the oxide film or other hardened layer formed by the casting and forging process, it is appropriate to use reverse milling.

6. Carbide end mill high quality use

The use of high-speed steel end mills and the use of a wider range of requirements, even if the choice of cutting conditions is slightly improper, it is not too big a problem. While carbide end mill has good wear resistance when cutting at high speed, but its range of use is not as wide as that of HSS end mill, and the cutting conditions must be strictly in line with the requirements of the tool.

Carbide end mill high quality is usually coated with anti-rust oil when it leaves the factory, if non-water-soluble cutting oil is used when cutting, a mist oil film will be attached to the inner hole of the tool holder, when the oil film exists on both the shank and the tool holder, it is difficult for the tool holder to clamp the shank firmly, and the end mill will easily fall off during processing. Therefore, before the end mill is clamped, the shank of the end mill and the inner hole of the tool holder should be cleaned with cleaning liquid and dried before clamping.

Since there is a small gap between the end mill and the tool holder, the tool may vibrate during the machining process. The vibration will make the end mill circumferential edge eat unevenly and increase the cutting expansion than the original value, which will affect the machining accuracy and tool life.

3.Carbide end mill high quality end edge cutting

In the CNC milling processing of mold and other workpiece cavities, when the cutting point is a concave part or deep cavity, the extension of the end mill needs to be lengthened. If a long end mill is used, the deflection of the tool will cause vibration and tool breakage.

Therefore, if only the cutting edge near the end of the tool is required to participate in the machining process, it is better to use a short-edge long-shank end mill with a longer total tool length.

4. The choice of cutting parameters

The choice of cutting speed mainly depends on the material of the workpiece to be machined; the choice of feed rate mainly depends on the material of the workpiece to be machined and the diameter of the end mill. Some foreign tool manufacturer's tool samples with cutting parameters selection table, can be referred to.

5. The choice of cutting mode

The use of smooth milling is conducive to preventing damage to the cutting edge, which can improve tool life. But there are two points need to pay attention to.

① such as the use of ordinary machine tool processing, should try to eliminate the clearance of the feed mechanism.

②When the surface of the workpiece is left with the oxide film or other hardened layer formed by the casting and forging process, it is appropriate to use reverse milling.

6. Carbide end mill high quality use

The use of high-speed steel end mills and the use of a wider range of requirements, even if the choice of cutting conditions is slightly improper, it is not too big a problem. While carbide end mill has good wear resistance when cutting at high speed, but its range of use is not as wide as that of HSS end mill, and the cutting conditions must be strictly in line with the requirements of the tool.