4 Flute Square End Mills in the actual processing of the role and safe maintenance

May 11, 2021|

May 11, 2021| View:895

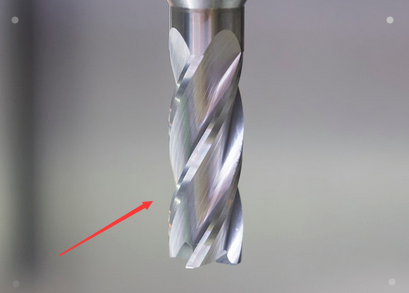

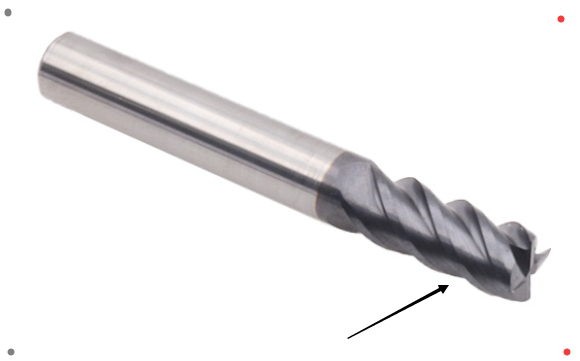

View:8954 Flute Square End Mills generally have a small number of cutting edges and large chip holding slots, so the chip discharge can be smoother, but because the cross-sectional area of 4 Flute Square End Mills is small, the rigidity of the tool body is low and the tool body is prone to bending during cutting. Its rigidity is inversely proportional to the third power of the edge length. Therefore, if the edge length is doubled, the rigidity of the four-flute end mill will be reduced to 1/8 of the original one.

In actual field processing, customers mostly use 4 Flute Square End Mills to process flat surfaces, steps, etc. 4 Flute Square End Mills use right-handed, right-cutting spiral teeth, so that chips are discharged from the front of the milling cutter when processing materials. The 4 Flute Square End Mills have a better chip removal effect and increase the cutting front angle, reducing the chip volume and making it easier to cut the material, so the 4 Flute Square End Mills are widely used in the fields of mold processing and auto parts production.

Safety rules of 4 Flute Square End Mills.

1. loading and unloading workpieces, must move away from the tool, cutting in the head, hands must not be close to the milling surface.

2. When using the milling machine to the tool, must be slow or hand-cranked into, not fast.

3. Fast into the back of the tool to pay attention to the milling machine handle will not hit people.

4. Into the tool not too fast, not allowed to suddenly change speed, milling machine limit block should be adjusted.

5. Up and down and measurement of the workpiece, adjust the tool, tighten the variable speed, must stop the milling machine.

6. dismantling and assembling the end mill, the work table should be padded with wooden boards, remove the flat milling tool wrench nut, the force must not be too hard.

4 Flute Square End Mills maintenance rules.

1. First of all, the end face of the knife blade should be ground flat perpendicular to the axis. Place the 4 Flute Square End Mills on a flat surface with the cutting edge facing downward and observe the tilt angle from left to right. Then rotate the milling cutter 180° and then observe its left and right tilt angle. If the tilt angle observed twice in the same direction is different, it needs to be resharpened until the tilt angle observed twice in the same direction is the same. After that, rotate the milling cutter 90° again and repeat the above action. Then use a right angle ruler to correct. On a flat plate with 90° right angle ruler correction, put the milling cutter and the right angle ruler both flat and observe whether there is a gap between the milling cutter and the right angle ruler or whether the gap is uniform, then judge the verticality of the milling cutter according to the gap and resharpen the milling cutter. For self-correction, clamp the end mill on the drill press or milling machine chuck, put a used grinding wheel piece underneath, select the appropriate speed to turn on the machine, then move down the milling cutter to grind on the grinding wheel piece, and offer grinding according to the end grinding.

2. Cleaning

(1) Disassemble and clean the oil felt pads of each ministry.

(2) Wipe each sliding surface and guideway surface, wipe the table and lateral, lifting screw, wipe the tool walking transmission mechanism and tool holder.

(3) wipe the dead corner of each ministry.

3. Lubrication

(1) Each oil hole is clean and smooth and filled with lubricant.

(2) each guide surface and sliding surface and each screw fill with lubricating oil.

(3) Check the oil tank body of the transmission mechanism, oil surface, and refuel to the elevated position.

4. Anti-corrosion

(1) Remove rust and corrosion in all parts, protect the painted surface and do not collide.

In actual field processing, customers mostly use 4 Flute Square End Mills to process flat surfaces, steps, etc. 4 Flute Square End Mills use right-handed, right-cutting spiral teeth, so that chips are discharged from the front of the milling cutter when processing materials. The 4 Flute Square End Mills have a better chip removal effect and increase the cutting front angle, reducing the chip volume and making it easier to cut the material, so the 4 Flute Square End Mills are widely used in the fields of mold processing and auto parts production.

Safety rules of 4 Flute Square End Mills.

1. loading and unloading workpieces, must move away from the tool, cutting in the head, hands must not be close to the milling surface.

2. When using the milling machine to the tool, must be slow or hand-cranked into, not fast.

3. Fast into the back of the tool to pay attention to the milling machine handle will not hit people.

4. Into the tool not too fast, not allowed to suddenly change speed, milling machine limit block should be adjusted.

5. Up and down and measurement of the workpiece, adjust the tool, tighten the variable speed, must stop the milling machine.

6. dismantling and assembling the end mill, the work table should be padded with wooden boards, remove the flat milling tool wrench nut, the force must not be too hard.

7. It is strictly forbidden to touch or use cotton yarn to rub the rotating parts and tools, and forbid to use hands to hold the tool plate.

4 Flute Square End Mills maintenance rules.

1. First of all, the end face of the knife blade should be ground flat perpendicular to the axis. Place the 4 Flute Square End Mills on a flat surface with the cutting edge facing downward and observe the tilt angle from left to right. Then rotate the milling cutter 180° and then observe its left and right tilt angle. If the tilt angle observed twice in the same direction is different, it needs to be resharpened until the tilt angle observed twice in the same direction is the same. After that, rotate the milling cutter 90° again and repeat the above action. Then use a right angle ruler to correct. On a flat plate with 90° right angle ruler correction, put the milling cutter and the right angle ruler both flat and observe whether there is a gap between the milling cutter and the right angle ruler or whether the gap is uniform, then judge the verticality of the milling cutter according to the gap and resharpen the milling cutter. For self-correction, clamp the end mill on the drill press or milling machine chuck, put a used grinding wheel piece underneath, select the appropriate speed to turn on the machine, then move down the milling cutter to grind on the grinding wheel piece, and offer grinding according to the end grinding.

2. Cleaning

(1) Disassemble and clean the oil felt pads of each ministry.

(2) Wipe each sliding surface and guideway surface, wipe the table and lateral, lifting screw, wipe the tool walking transmission mechanism and tool holder.

(3) wipe the dead corner of each ministry.

3. Lubrication

(1) Each oil hole is clean and smooth and filled with lubricant.

(2) each guide surface and sliding surface and each screw fill with lubricating oil.

(3) Check the oil tank body of the transmission mechanism, oil surface, and refuel to the elevated position.

4. Anti-corrosion

(1) Remove rust and corrosion in all parts, protect the painted surface and do not collide.

(2) Discontinue use, spare equipment guide surface, sliding screw handwheel and other exposed parts prone to rusting are coated with oil to prevent corrosion.